Core Moto Wheels Apex-6 Kawasaki Ninja ZX10R 2016-2025 Forged

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

Proudly made in the USA.

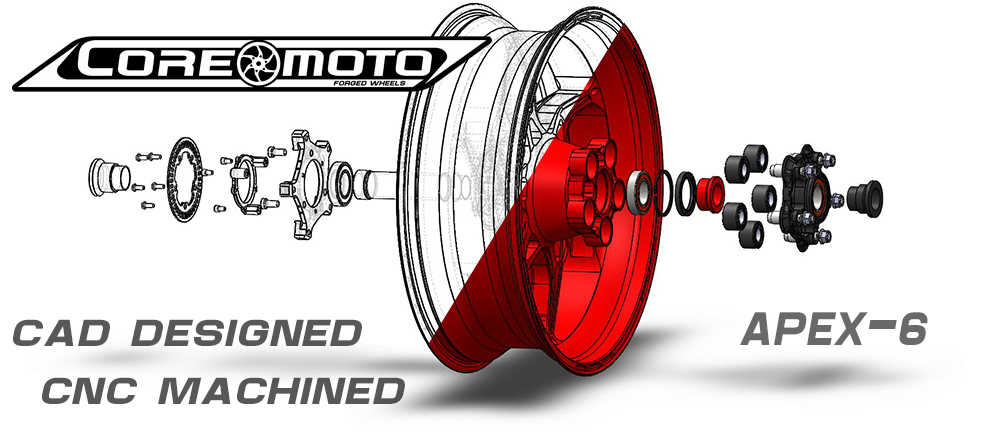

Core Moto Apex-6 Ultralight Superbike.

FORGED ALUMINUM WHEEL SET

- Sold as a set: Front and Rear.

- No modification to vehicle required.

- Sold/Shipped fully assembled, Ready to install.

- Includes all Spacers, bearings and Accepts OEM Rotors.

- Only an aftermarket Sprocket with performance wheel bolt pattern is required.

- *1 FREE Sprocket of included with order (must choose OEM option in both fields to receive free sprocket).

**If the Free OEM sprocket option is chosen, you will receive an aftermarket, black sprocket of the

same pitch and tooth count that came on your bike from the factory. Only the bolt pattern is different.

If you need a different pitch and tooth count, you can choose one at a reduced cost.

Sprockets for Core Moto Wheels are available from most sprocket manufacturers.

The optimized bolt pattern is shared by most high performance superbike wheel manufacturers.

STREET / TRACK USE

DOT - JWL

Size: Front 3.50"x17" / Rear 6.00"x17"

Bare Wheel weights.

FW35LM1 Front: 5.79 Lbs

RW6LM1 Rear: 7.96 Lbs

Fully Assembled Apex-6 wheel Weights.

Includes all components and mounting hardware..No parts omitted to achieve lower published weight.

16-23 ZX10 Front: 7.6 LBS

16-23 ZX10 Rear: 11.27 LBS

Total set weight Fully assembled: 18.87lbs

Standard Available Anodized wheel Colors:

Gloss Gold

Gloss Black

Gloss Blue

Gloss Red

NEW: Gloss Light Gold

Note: Anodized colors can vary from batch to batch. Wheel sets are paired as front and rear sets in the anodize process... Very slight shade differences from front to rear may be present when sold as a pair, but will remain under a 5% range. In most cases this is undetectable when the wheels are mounted on the vehicle.

Colors / Finishes Available for Custom Order / Added lead time and prices.

Raw Machine finish**

Clear Bright Anodized

Gloss Purple Anodized

Gloss Ti-Gray Anodized

Gloss Green Anodized

Gloss Orange Anodized

Satin Black Anodized

Satin Gold Anodized

Satin Blue anodized

Satin Red anodized

Satin Gray anodized

Satin Purple Anodized

**Raw finish means the wheel bodies have had no surface finishing treatment or protective coating. This option is only for customers who wish to have the wheels Painted, powdercoated or anodized themselves. Raw Machine finished wheels are sold with all components but are not assembled and carry no factory warranty since the wheels can be damaged in the finishing process if not done properly. Buyer assumes all risks.

Custom Limited Colors and finishes.

Core Moto may release limited run custom colors from time to time. Core Moto will list these custom wheel sets on our website when available and will not accept order cancelations.

About our bearings:

Always factory equipped with high quality, smooth rolling bearings from genuine top tier bearing manufacturers..... Currently the availability of counterfeit bearings is a worldwide epidemic. Core Moto only sources genuine brand name bearings from top tier bearing distributors or factory direct to ensure tolerances and material compositions meet specifications. Our bearings are in most cases larger and wider than stock for more stability. We also choose a bearing seal type that is suited for long service life when maintained properly. Ceramic hybrid bearings are available upon request as an upgrade. We only suggest using ceramic bearings on regularly maintained race specific bikes.

Cush drive bushings:

New wheels made by Core Moto come with serviceable 5 or 6 pot cylindrical Cush Drive System for High HP Applications. In 2016 Core Moto developed a new Cush drive bushing that has proven durability. Our new bushing is now a single bonded hardened steel and firmer compound rubber unit. If your wheels were made before Core Moto started producing Carrozzeria wheels in 2016, improved bushings can be ordered in our genuine replacement parts section or from your favorite Core Moto dealer. As of 2019 we have 3 bushing sizes, depending on wheel model.

Sprocket Carrier:

New 5 bolt anodized CNC aluminum sprocket carrier for Apex-6 models are .25lb lighter than former 6 bolt Carriers. Each comes with, pressed in studs, metal locking sprocket nuts, bearing retaining ring and bearing for all models. Our sprocket studs are fully re designed, stronger and offer superior corrosion resistance. The drive stud head profile has been optimized to offer more engagement of the bushing system for even load distribution per unit. The Bolt pattern for the Apex-6 is NOT A KAWASAKI PATTERN. The Apex-6 uses a common custom 5 bolt sprocket made by most major manufacturers. More information on sprockets below. or Sprockets can be purchased at this link

Spacers and distance tubes:

Anodized CNC aluminum Spacers, Carriers and Distance Tubes are pre installed in the wheel set. Some spacers may be shipped uninstalled for wheel packing reasons, but will come with a diagram for easy placement. Each part is either laser or mechanically engraved with unique part numbers to identify the placement location. Most front wheel spacers are now fully captive using oil seals. Outer rear spacers are captive by bearing ID sleeves.

Rotor Carriers:

Rotor carriers will be pre mounted with stainless steel hardware as to not interfere with modern wheel speed sensor pickups. All rotor carriers are designed to accept OEM or aftermarket equivalent brake rotor discs and rotor bolts. New carriers are designed to optimize weight savings while offering a very rigid mount.

Speed sensor rings for ABS and TC:

Core Moto is now starting to incorporate our own speed sensor rings into the final product, allowing the customer to keep their sensor rings on their OEM wheels in some cases. Core Moto was the first aftermarket wheel manufacturer in the industry to do this. This has not been fully implemented for all applications as we are adding them as we make new changes to the hardware. Some application will require reuse of both OEM rings while some applications may come with only one Core Moto Ring front or rear. Each application is different. Applications where the sensor ring mounts to the outside of the rotor will not come with Core Moto speed sensor rings and will require re using OEM rings.

Valve stems:

Each wheel will come with 90 degree aluminum valve stems installed.

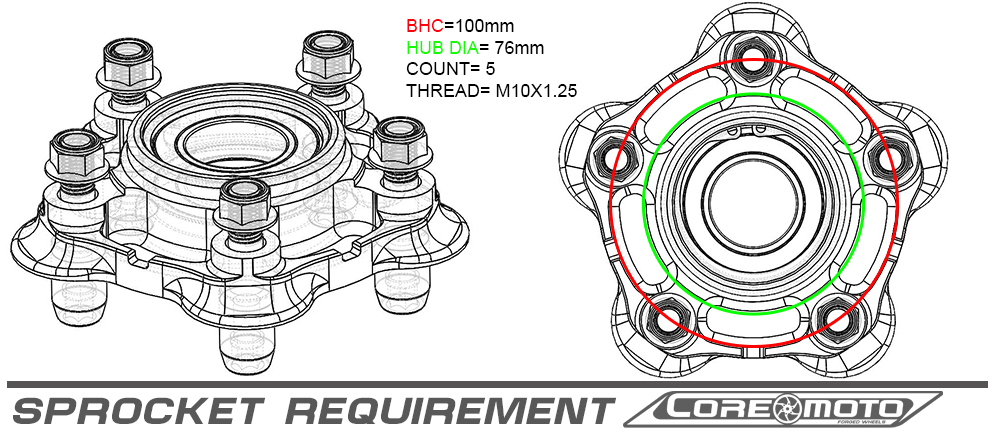

Sprocket requirement:

Due to the bolt circle diameter of the cush drive system, All Apex-6 Wheels require the use of a custom 5 bolt pattern sprocket.

This is a common sprocket bolt pattern used by other aftermarket forged wheel companies in our industry and available from most sprocket manufacturers.

You will need a sprocket to fit your current pitch 520-530. Then the proper tooth count.

Bolt hole count: 5

Sprocket stud size: M10x1.25

Bolt Hole Circle diameter: 100mm

Hub Diameter: 76mm

Approved DOT (USA) & JWL (Japan)

One year limited warranty

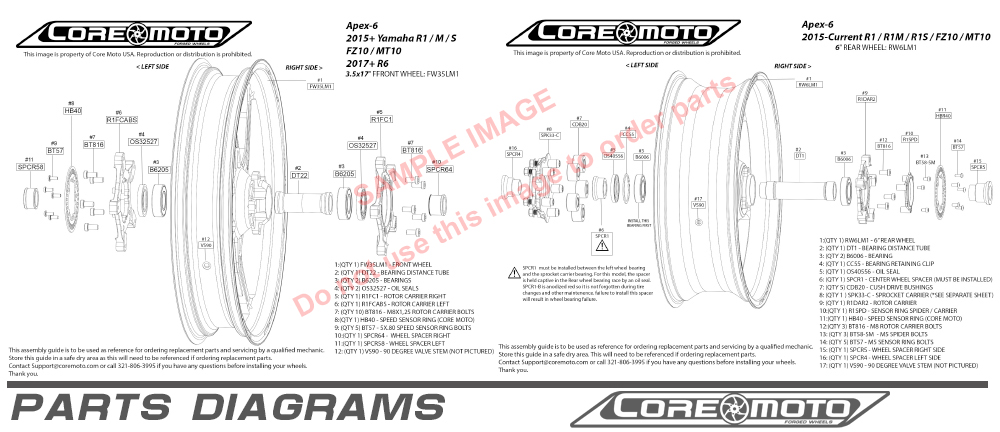

Parts diagram: Exploded view parts diagrams are included with most wheels orders. These are to be used to ensure you received the correct parts and put them in the right place when installing your wheel kit. This is to be kept for future use in case you need a new part due to loss or damage.

NOTE: The diagram image below is a sample image of the diagram you will receive, not of the application in this listing.

Product Specs

| SKU: | ZX104A6 |

|---|

Related Products

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per

- $2,949.00

$2,949.00- $2,949.00

- Unit price

- per