- Home »

- Catalog

HHR Performance » 2009, Yamaha

Products for:

- Year: 2009

- Make: Yamaha

View Universal items for: 2009 Yamaha

Browse Products

SOLO 2 Mounting

Works with SOLO 2 and Solo 2 DL

Genuine AIM Quality

Note: (Springs Sold Separately Use Springs Series 08790-)

NIX 30 Cartridge Kit FGK 202

Our 30 mm front fork cartridge kit is based on experience gained from international Supersport and Superstock championships. It doesn’t matter if you are heading for a national road racing title or if you are taking your bike to the local race track. The cartridge kit will give you loads of performance, stable damping characteristics and fantastic comfort.

The kit has a unique design with compression damping and the adjustment on the left leg and rebound damping

and the adjustment on the right leg – i.e. all adjustments are made at the top together with the spring preload!

The cartridge kit system fits bolt on in most standard hyper sport front forks.

Part number

FGK 202

Type Code

30mm Cartridge Kit R&T

Technical data

| Stroke: | 120 mm |

|---|---|

| Position: | front |

| Spring series: | 08790-Serie |

Notes

It is recommended to contact an authorised ÖHLINS Service Center for installation.

Fits for vehicles

Yamaha YZF-R6 (2008 – 2015)

- Teilegutachten (Germany)

- "ABE" in preparation (Germany)

Download

- Mounting Instructions FGK 210 English (552,0 KB)

- Owner´s Manual 30mm Cartridge Kit Road & Track English (1.996,0 KB)

- Mounting Instructions FGK 210 German (608,3 KB)

- Owner´s Manual 30mm Cartridge Kit Road & Track German (2.541,2 KB)

FKR Cartridge Kit Racing (TTX 25) FKR 112

The racing inspired FKR cartridge kit has technology derived straight from the Moto3, Moto 2 and World Superbike championships developed by our engineers in Sweden and is designed for high end racing.

The FKR Cartridge kit features a spring pressurized system, compared to the old gas pressurized system, the spring pressure offers a more simplistic and user friendly design that also accounts for easier maintenance. But there are more advantages of a spring pressurized system. There is no risk of gas leakage, it also gives a more consistent performance curve and allows for a more compact design. With the Öhlins TTX technology, a new designed piston and an 8mm piston shaft we reduce the pressure build-up and create a faster damping response. That gives a “linear” style of damping characteristics which create more tuning options and also increases grip and bump absorption properties while improving chassis stability.

Part number

FKR 112

Type Code

TTX25 Cartridge Kit FKR

Technical data

| Spring series: | 04744-Serie |

|---|---|

| Packaging included: | springs 9.0, 9.5, 10.0 |

Notes

It is recommended to contact an authorised ÖHLINS Service Center for installation.

Fits for vehicles

Yamaha YZF-R6 (2008 – 2015)

- Racing product, not for use on public roads

Download

- Mounting Instructions FKR 112 English (755,2 KB)

- Owner´s Manual TTX GP shock absorber Road & Track (English) (971,6 KB)

- Mounting Instructions TR 469 German (728,0 KB)

- Owner´s Manual TTX GP shock absorber Road & Track (German) (1.098,1 KB)

- FKR 100 Öhlins Product News (German) (1.000,6 KB)

The new and improved model BOOST carbon fiber wheel from Rotobox, decreasing the weight from the RBX2 with improved design and higher performance! Comes in gloss and matte finish, in both symmetric and convex designs.

Like the RBX2, the BOOST is produced using Rotobox's unique 3-component composite - combining carbon, epoxy and stainless steel. By integrating the stainless 2,5 mm steel wire in each side of the rim, we increase its impact resistance at the most critical outer part. JWL and DOT approved, having met JASO T203-85 safety standards.

Another hidden BOOST gem - the Structural Rib. Thanks to the High Pressure Core Technology the structural rib is placed in the inner side between the spokes, with its mission to support the stress hot spot of the wheel. As a result the BOOST elegant spoke design brings greater stiffness and although the spokes are thinner the BOOST is stronger than ever - with a permissible static load of 280 kg on the rear and 180kg on the front wheel.

ASSEMBLING COMPONENTS

Carbon fiber composite rim, a one-piece hollow carbon cast, reinforced with stainless steel wire and UV protected; 7075 T6 aluminum alloy hubs, spacers and sprocket carrier [only with rear symmetric wheel]. machined from solid and hard anodized; polyurethane cushion drive set; SKF bearings; aluminum valve stem.

PRODUCT QUALITY CONTROL

Your Rotobox wheel has its own Serial Number to track the production history. We confirm to have performed quality verification procedure of your Rotobox wheel.

SIZE

17" x 3.5"

WEIGHT

REAR WHEEL WEIGHT 2.58 kg / 5.68 LBS

MAX. STATIC LOAD

REAR 180 kg / 400 LBS

MAX. OPERATING TEMPERATURE

100 C / 212 F

MAX. PRESSURE

4 BAR / 58 PSI

The wheels conform to safety standard JASO T203-85 for JWL dotE Certification. Before riding on public streets, be sure to check your local regulations.

Rotobox Boost Wheel set Weight example:

Stock S1000RR 11.70kg (25.79 lbs)

Rotobox Boost 6.69kg (14.74 lbs)

Weight saving more than 5.00kg of rotating mass. Incredible!

The new and improved model BOOST carbon fiber wheel from Rotobox, decreasing the weight from the RBX2 with improved design and higher performance! Comes in gloss and matte finish, in both symmetric and convex designs.

Like the RBX2, the BOOST is produced using Rotobox's unique 3-component composite - combining carbon, epoxy and stainless steel. By integrating the stainless 2,5 mm steel wire in each side of the rim, we increase its impact resistance at the most critical outer part. JWL and DOT approved, having met JASO T203-85 safety standards.

Another hidden BOOST gem - the Structural Rib. Thanks to the High Pressure Core Technology the structural rib is placed in the inner side between the spokes, with its mission to support the stress hot spot of the wheel. As a result the BOOST elegant spoke design brings greater stiffness and although the spokes are thinner the BOOST is stronger than ever - with a permissible static load of 280 kg on the rear and 180kg on the front wheel.

ASSEMBLING COMPONENTS

Carbon fiber composite rim, a one-piece hollow carbon cast, reinforced with stainless steel wire and UV protected; 7075 T6 aluminum alloy hubs, spacers and sprocket carrier [only with rear symmetric wheel]. machined from solid and hard anodized; polyurethane cushion drive set; SKF bearings; aluminum valve stem.

PRODUCT QUALITY CONTROL

Your Rotobox wheel has its own Serial Number to track the production history. We confirm to have performed quality verification procedure of your Rotobox wheel.

SIZE

17" x 6.00"

WEIGHT

REAR WHEEL WEIGHT 4.11 kg / 9.06 LBS

MAX. STATIC LOAD

REAR 280 kg / 617 LBS

MAX. OPERATING TEMPERATURE

100 C / 212 F

MAX. PRESSURE

4 BAR / 58 PSI

The wheels conform to safety standard JASO T203-85 for JWL dotE Certification. Before riding on public streets, be sure to check your local regulations.

Rotobox Boost Wheel set Weight example:

Stock S1000RR 11.70kg (25.79 lbs)

Rotobox Boost 6.69kg (14.74 lbs)

Weight saving more than 5.00kg of rotating mass. Incredible!

The new and improved model BOOST carbon fiber wheel from Rotobox, decreasing the weight from the RBX2 with improved design and higher performance! Comes in gloss and matte finish, in both symmetric and convex designs.

Like the RBX2, the BOOST is produced using Rotobox's unique 3-component composite - combining carbon, epoxy and stainless steel. By integrating the stainless 2,5 mm steel wire in each side of the rim, we increase its impact resistance at the most critical outer part. JWL and DOT approved, having met JASO T203-85 safety standards.

Another hidden BOOST gem - the Structural Rib. Thanks to the High Pressure Core Technology the structural rib is placed in the inner side between the spokes, with its mission to support the stress hot spot of the wheel. As a result the BOOST elegant spoke design brings greater stiffness and although the spokes are thinner the BOOST is stronger than ever - with a permissible static load of 280 kg on the rear and 180kg on the front wheel.

ASSEMBLING COMPONENTS

Carbon fiber composite rim, a one-piece hollow carbon cast, reinforced with stainless steel wire and UV protected; 7075 T6 aluminum alloy hubs, spacers and sprocket carrier [only with rear symmetric wheel]. machined from solid and hard anodized; polyurethane cushion drive set; SKF bearings; aluminum valve stem.

PRODUCT QUALITY CONTROL

Your Rotobox wheel has its own Serial Number to track the production history. We confirm to have performed quality verification procedure of your Rotobox wheel.

SIZE

17" x 6.00"

WEIGHT

REAR WHEEL WEIGHT 4.11 kg / 9.06 LBS

MAX. STATIC LOAD

REAR 280 kg / 617 LBS

MAX. OPERATING TEMPERATURE

100 C / 212 F

MAX. PRESSURE

4 BAR / 58 PSI

The wheels conform to safety standard JASO T203-85 for JWL dotE Certification. Before riding on public streets, be sure to check your local regulations.

Rotobox Boost Wheel set Weight example:

Stock S1000RR 11.70kg (25.79 lbs)

Rotobox Boost 6.69kg (14.74 lbs)

Weight saving more than 5.00kg of rotating mass. Incredible!

Based on the highly regarded TTX technology it has been developed from Öhlins’ vast experience in MotoGP. Compared with the standard TTX36 MkII, the compression and rebound adjustments have improved even further with a new adjustment needle, providing better guidance and a different flow restriction behavior. The function of the damper is more consistent with less variation and the adjusters work in a more precise manner. A new main piston completes the package, designed to improve traction and rider control. Did we mention that the weight is reduced even further? Among the advantages are a much improved chassis feedback as well as enhanced performance. Also, the adjustment range is even wider and with this new design, the variation in behavior from one shock absorber to another is further reduced – a proof of Öhlins commitment to precision. The TTX GP continues on the TTX36 path, sharing and improving on the benefits of one of the best shock absorbers in the world. TTX GP will be available for most major bikes used in national racing as well as the new street bike models.

Specs

Based on the highly regarded TTX technology it has been developed from Öhlins’ vast experience in MotoGP. Compared with the standard TTX36 MkII, the compression and rebound adjustments have improved even further with a new adjustment needle, providing better guidance and a different flow restriction behavior. The function of the damper is more consistent with less variation and the adjusters work in a more precise manner. A new main piston completes the package, designed to improve traction and rider control. Did we mention that the weight is reduced even further? Among the advantages are a much improved chassis feedback as well as enhanced performance. Also, the adjustment range is even wider and with this new design, the variation in behavior from one shock absorber to another is further reduced – a proof of Öhlins commitment to precision. The TTX GP continues on the TTX36 path, sharing and improving on the benefits of one of the best shock absorbers in the world. TTX GP will be available for most major bikes used in national racing as well as the new street bike models.

Specs

ASSEMBLING COMPONENTS

Carbon fiber composite rim, a one-piece hollow carbon cast, reinforced with stainless steel wire and UV protected; 7075 T6 aluminium alloy hubs, spacers and sprocket carrier [only with rear symmetric wheel]. machined from solid and hard anodized; polyurethane cushion drive set; SKF bearings; aluminium valve stem.

PRODUCT QUALITY CONTROL

Your Rotobox wheel has its own Serial Number to track the production history. We confirm to have performed quality verification procedure of your Rotobox wheel.

SIZE

17" x 3.5"

WEIGHT

REAR WHEEL WEIGHT 2.58 kg / 5.68 LBS

MAX. STATIC LOAD

REAR 150 kg / 330 LBS

MAX. OPERATING TEMPERATURE

100 C / 212 F

MAX. PRESSURE

4 BAR / 58 PSI

The wheels conform to safety standard JASO T203-85 for JWL dotE Certification. Before riding on public streets, be sure to check your local regulations.

The complete set of RBX2 wheels, without brake rotors and sprocket, weighs:

6,65 kg (14.6 lbs) for Kawasaki ZX10R

6,61 kg (14.5 lbs) for Aprilia RSV4

6,90 kg (15.1 lbs) for BMW S1000RR

5,35 kg (11.6 lbs) for Ducati 1199 Panigale

ASSEMBLING COMPONENTS

Carbon fiber composite rim, a one-piece hollow carbon cast, reinforced with stainless steel wire and UV protected; 7075 T6 aluminium alloy hubs, spacers and sprocket carrier [only with rear symmetric wheel]. machined from solid and hard anodized; polyurethane cushion drive set; SKF bearings; aluminium valve stem.

PRODUCT QUALITY CONTROL

Your Rotobox wheel has its own Serial Number to track the production history. We confirm to have performed quality verification procedure of your Rotobox wheel.

SIZE

17" x 6.0"

WEIGHT

REAR WHEEL WEIGHT 4.11 kg / 9.06 LBS

MAX. STATIC LOAD

REAR 250 kg / 550 LBS

MAX. OPERATING TEMPERATURE

100 C / 212 F

MAX. PRESSURE

4 BAR / 58 PSI

The wheels conform to safety standard JASO T203-85 for JWL dotE Certification. Before riding on public streets, be sure to check your local regulations.

The complete set of RBX2 wheels, without brake rotors and sprocket, weighs:

6,65 kg (14.6 lbs) for Kawasaki ZX10R

6,61 kg (14.5 lbs) for Aprilia RSV4

6,90 kg (15.1 lbs) for BMW S1000RR

5,35 kg (11.6 lbs) for Ducati 1199 Panigale

ASSEMBLING COMPONENTS

Carbon fiber composite rim, a one-piece hollow carbon cast, reinforced with stainless steel wire and UV protected; 7075 T6 aluminium alloy hubs, spacers and sprocket carrier [only with rear symmetric wheel]. machined from solid and hard anodized; polyurethane cushion drive set; SKF bearings; aluminium valve stem.

PRODUCT QUALITY CONTROL

Your Rotobox wheel has its own Serial Number to track the production history. We confirm to have performed quality verification procedure of your Rotobox wheel.

SIZE

17" x 6.0"

WEIGHT

REAR WHEEL WEIGHT 4.11 kg / 9.06 LBS

MAX. STATIC LOAD

REAR 250 kg / 550 LBS

MAX. OPERATING TEMPERATURE

100 C / 212 F

MAX. PRESSURE

4 BAR / 58 PSI

The wheels conform to safety standard JASO T203-85 for JWL dotE Certification. Before riding on public streets, be sure to check your local regulations.

The complete set of RBX2 wheels, without brake rotors and sprocket, weighs:

6,65 kg (14.6 lbs) for Kawasaki ZX10R

6,61 kg (14.5 lbs) for Aprilia RSV4

6,90 kg (15.1 lbs) for BMW S1000RR

5,35 kg (11.6 lbs) for Ducati 1199 Panigale

• Upper Race Fairing (6 Dzus)

• Lower Fairing (5 Dzus)

• Left Side Panel

• Right Side Panel

• Superbike Tail

• Upper Race Fairing (8 Dzus)

• Lower Fairing (4 Dzus)

• Left Side Panel

• Right Side Panel

• Single Race Seat (3 Pcs)

There are 3 options for seats

Basic - This seat is a 15mm neoprene foam glued to a base that is molded from the seat pan of the tail section and then attaches to the seat pan with bolts. Please not that these seat's will only fit carbonin seat pans and seat units. It will not work on any other brand. This foam will wear out like any other foam pad.

Standard - This is an upgrade to the basic seat which is covered in a neoprene material that protects the basic foam and provides the rider a level of grip but without compromising the need to slide side to side. It looks much more professional and will protect the basic foam from any wear from patches on leather suits or abuse from side to side movements. we have seen these seats go on for 3 seasons or more!

Pro Seat - This seat is for riders or teams that require their seat to provide back support or a step seat to keep them in a position from sliding too far back in the seat under acceleration, this is often done with a raised section so they can still get back in the seat in the full tuck, they are just raised up more which helps keep the butt up and their head shoulders and chest lower in the tuck. It is the same material as the standard seat but can also be customized with team logo's or race number -If you purchase a pro seat we will contact you to design your seat. Please note pro seats are made custom to order

This new patented device is called "Oversuspension" - OverSuspension is a special resonator capable of removing the resonances of the rear swingarm group and giving the vehicle more stability, traction, braking and comfort, as well as facilitating the dynamic operation of the suspension, and greatly improving driving safety in every condition, for example reducing the possibility of highside on the track by up to 90%.

This new patented device is called "Oversuspension" - OverSuspension is a special resonator capable of removing the resonances of the rear swingarm group and giving the vehicle more stability, traction, braking and comfort, as well as facilitating the dynamic operation of the suspension, and greatly improving driving safety in every condition, for example reducing the possibility of highside on the track by up to 90%.

V02569190

Quick Info

SOLO Harness

Works with SOLO

Genuine AIM Quality

Product Details

SOLO DL Yamaha R6/R1 ECU interface harness*

SOLO Harness

Works with SOLO

Genuine AIM Quality

Product Details

SOLO DL Yamaha R1 ECU interface harness*

The lithium ATZ-10-RS is a direct replacement for these OEM battery sizes:

YTZ10S

YTZ12

YTZ14

YTX9

YTX7A-BS

YT12A-BS

- The switch is a direct plug and play replacement for OEM right handlebar engine switch for previous generation Yamaha R6 2008-2016

- Ideal for racing and street application, to save space and weight where it matters.

- Replaces OEM plastic handlebar switch with billet aluminum switch housing, providing weight and space savings and superior crash resistance.

- Designed for 22 mm standard clip on handle bars.

- Switch functions: engine run/stop (maintained top), starter activation (momentary bottom)

- Designed and CNC machined in United States from aircraft grade aluminum to be the smallest and lightest on the market.

- Premium, military grade buttons with gold plated contact surfaces, manufactured in United States by Otto Engineering.

- Comes Plug and play with OEM connector.

- Also available in master brake cylinder mounted switch housing. Part # YR616R2EMRCS

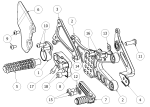

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA To Fit with Attack Clipon Tubes Please Note these DO not fit with all aftermarket clipons At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA To Fit with Attack Clipon Tubes Please Note these DO not fit with all aftermarket clipons At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

MADE IN USA At Attack Performance they have set up many championship winning chassis along with designing, manufacturing, and building our own MotoGP machine with their own parts. Attack Performance utilizes chassis simulation software to find critical dimensions such as Rake, Trail, Wheel Forces, and Linkage Ratios, just to name a few. Those tools combined with their decades of racing eliminates the guesswork from chassis setup.

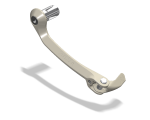

Designed specifically for the Yamaha R6 or R1, this Brake Lever from Bonamici will improve the look and feel of the hand levers on your Yamaha. Bonamici Levers are made from a single piece of billet aluminium in their factory based in Italy, with a black anodised finish for corrosion resistance and durability. These levers are incredibly high quality and offer great value for money, making them perfect for the Track Day warrior!

Designed specifically for the Yamaha R6 or R1, this Brake Lever from Bonamici will improve the look and feel of the hand levers on your Yamaha. Bonamici Levers are made from a single piece of billet aluminium in their factory based in Italy, with a black anodised finish for corrosion resistance and durability. These levers are incredibly high quality and offer great value for money, making them perfect for the Track Day warrior!

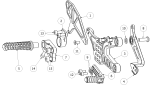

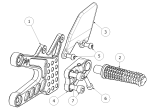

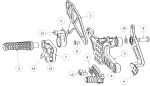

Bonamici Rearsets are made from a single piece of billet aluminium in their factory based in Italy, with a black anodised finish for corrosion resistance and durability. These Rearsets are incredibly high quality. To ensure compatibility, Bonamici laser scan each and every bike they manufacture parts for in order to ensure fitment, after this their parts are fine tuned, tested and validated through various levels of Motorsport meaning you can have complete confidence in these Rearsets to transform your R1! These Rearsets allow you to decide where you would like the footpegs to be mounted, featuring multiple different mounting positions you can rest assured that these Rearsets will improve the handling, comfort and appearance of your Yamaha R1!

Bonamici Rearsets are made from a single piece of billet aluminium in their factory based in Italy, with a black anodised finish for corrosion resistance and durability. These Rearsets are incredibly high quality. To ensure compatibility, Bonamici laser scan each and every bike they manufacture parts for in order to ensure fitment, after this their parts are fine tuned, tested and validated through various levels of Motorsport meaning you can have complete confidence in these Rearsets to transform your YZF-R6! These Rearsets allow you to decide where you would like the footpegs to be mounted, featuring multiple different mounting positions you can rest assured that these Rearsets will improve the handling, comfort and appearance of your Yamaha YZF-R6!

From the cooperation with racing teams from the Superbike World Championship, the aluminium engine cover protectors from Bonamici Racing were born. Manufactured from high quality billet aluminium and milled using the latest CNC technology, the anodised protector kits perfectly protect the bike’s engine housing in the event of a crash.

The lightweight aluminium protectors are simply screwed onto the original engine housing and guarantee a perfect fit.

No glue is needed!

High end quality made in Italy

From the cooperation with racing teams from the Superbike World Championship, the aluminium engine cover protectors from Bonamici Racing were born. Manufactured from high quality billet aluminium and milled using the latest CNC technology, the anodised protector kits perfectly protect the bike’s engine housing in the event of a crash.

The lightweight aluminium protectors are simply screwed onto the original engine housing and guarantee a perfect fit.

No glue is needed!

High end quality made in Italy

From the cooperation with racing teams from the Superbike World Championship, the aluminium engine cover protectors from Bonamici Racing were born. Manufactured from high quality billet aluminium and milled using the latest CNC technology, the anodised protector kits perfectly protect the bike’s engine housing in the event of a crash.

The lightweight aluminium protectors are simply screwed onto the original engine housing and guarantee a perfect fit.

No glue is needed!

High end quality made in Italy